Operator Safety

Instructions

INTRODUCTION1.

All operators should be trained to use

equipment correctly.

2. Appropriate protective

clothing especially Ear Defenders, High

Visibility Vests and Safety Boots should

be worn at all times.

3. This catalogue shows

Manufacturers Noise and Vibration levels

for all equipment. The information should

be used sensibly as part of a personnel

safety policy. In a practical environment

these levels can

increase or reduce depending on working

conditions and operator technique.

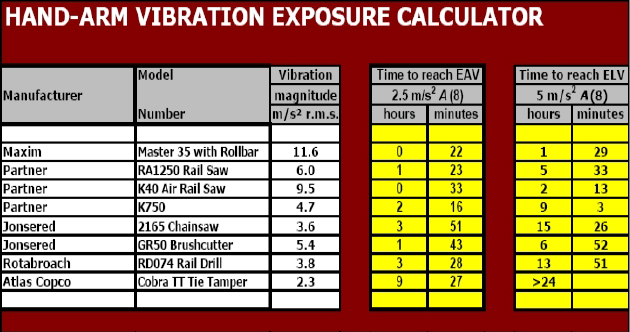

NEW VIBRATION

LEGISLATION EFFECTIVE 5TH JULY 2005

1. States the following :-

Daily Exposure Action and Limit Values

standardised to an eight hour

period

Action Level 2.5 m/s2

Limit 5.0 m/s2

2. This does not mean

Machines generating a higher level than

5.0m/s2 cannot be used, only that their

use may have to be restricted depending

on the circumstances.

3. Measure actual Trigger

time, not employee’s working time.

4. Using a high vibration

tool for a short time will produce a

lower overall exposure level than a low

vibration tool for a long time.

SOME WAYS TO REDUCE

VIBRATION EXPOSURE

1. Ensure equipment is

properly used and regularly maintained.

2. Ensure consumables e.g.

Impact Sockets and Cutters are in good

condition and not worn past their useful

life.

3. Review technique of using

equipment e.g. gripping too hard or

applying correct body pressure. A relaxed

technique is always better than a tense

one.

4. Use work rotation to

minimise exposure time for each employee.

Regular work breaks e.g, one hour on, one

hour off and one hour on is better than

two hours on.

5. Operators should keep

warm and dry.

6. Improve operators health

especially circulation. Smoking;

drinking; hardening of arteries; diet;

age; weight; high blood pressure all add

to the risk. Regular health checks will

help avoid some of these.

All information provided by

relevant manufacturers notes.

Times shown are TRIGGER time. I.E. Time

Operator experiences vibration NOT their

working time.

| RA1260 Rail

Saw |

Time of 5 hours and

33 minutes equates to

approximately 130 cuts in BS113A

Rail. |

| K40 Air Rail

Saw |

Time of 2 hours and

13 minutes equates to

approximately 50 cuts in BS113A

Rail. |

| K760 |

Time of 9 hours and

3 minutes equates to cutting

approximately 640 concrete paving

slabs. |

| TT Petrol

Tie Tamper |

Values are

considered lower than those

produced by typical Electric

Machines and present no

significant risk to operators

when used correctly. |

| F2111

Pneumatic Clip Remover |

Time of 1 hour and

49 minutes equates to the removal

of approximately 1300 clips. |

Master 35

Petrol Driven Impact Wrench Vibration

Guide

On extensive on-track trials carried out

under the independent supervision of

Loughborough University in February 2008

the undernoted results were achieved on

loosening and tightening:

Fishplate/Joint Bar Bolts

11.2 to 11.6m/s2 in approximately three

seconds. 430 bolts before reaching EU

Action Level and 1800 to reach Limit

Level.

Chairscrews/Lagscrews

9.8 to 11.0m/s2 in approximately seven

seconds. 240 screws before reaching EU

Action Level and 1000 to reach Limit

Level.

See OPERC website: www.operc.com

The actual figures achieved can vary

depending on operator technique and

condition of Wrench, fastener and track

Exploded diagram

drawings and parts lists for all Tools

and Equipment we supply are available on

request or from manufacturer's websites.

Master 35 Petrol Driven Impact Wrench: www.airtecinternational.com

Husqvarna: www.husqvarna.com/uk

Rotabroach: www.rotabroach.co.uk

Atlas Copco: www.atlascopco.com

We only supply

Manufacturer's genuine original spare

parts.

All popular spare parts are available

from stock at competitive prices.

|